Alpha Olefin Market Size, Share & Trends Analysis Report By Product (1-Hexene, 1-Octene), By Application (Polyethylene, Detergent Alcohol, Synthetic Lubricants), And Segment Forecasts, 2019 - 2025

- Report ID: 978-1-68038-356-0

- Number of Pages: 110

- Format: Electronic (PDF)

- Historical Range: 2014 - 2017

- Industry:leyu888

Industry Insights

The global alpha olefin market size was estimated at USD 8.26 billion in 2018 and is estimated to expand at a CAGR of 4.8% from 2019 to 2025. Growing demand for polyethylene, owing to its usage in various applications, such as packaging, industrial processes, consumer goods, and others is expected to drive the market. Alpha olefins are organic compounds produced by the oligomerization of ethylene, which is the most commonly used process. The oligomerization process consists of products with even-numbered carbon chains, usually ranging from C4 to C30+.

Different companies, such as Chevron, Shell, and Phillips, have developed their manufacturing techniques. Modifications by these producers at different stages of the reaction sequence lead to different products and chain-length of alpha-olefin polymers. Ethylene, which is manufactured using crude oil and naphtha, is the major raw material used in the production of alpha-olefin. The shale gas boom of 2008 in North America led to a dramatic decrease in the cost of industrial energy and feedstock.

Shale rocks can also be used as innovative, inexpensive cracker feed for ethylene production, which has resulted in increased supply levels coupled with lower market pricing. Investments in various cracker joint venture projects along with the abundant availability of low-cost ethane from reserves of shale gas in the U.S. are projected to boost raw material supply for the production of alpha-olefin. The market is anticipated to witness a stable demand-supply over the forecast period. Key companies, such as INEOS, SASOL, and CPChem, have invested in capacity expansion to help retain the market balance, as well as product prices.

However, the market is projected to witness a linear increase in product prices in line with a rise in the cost of ethylene over the forecast period. The prices are normally based on raw material costs and the production technology used. Ethylene prices have been fluctuating in the past and thus a similar trend can be observed with alpha-olefin prices. A decrease in ethylene prices in 2012 on account of the shale gas boom in the U.S. has directly affected the product prices.

Product Insights

1-hexene is expected to emerge as the fastest-growing product segment over the forecast years. Increasing utilization of 1-hexene as a common monomer for manufacturing High-Density Polyethylene (HDPE) and Linear Low-Density Polyethylene (LLDPE) polymers is expected to augment the segment growth. Rising demand for polyethylene on account of growing automotive and consumer goods markets, in the emerging economies of China, India, and Brazil is expected to drive the 1-hexene segment further.

It is also used as an additive in synthetic lubricants, which is expected to further augment market development. Demand for 1-dodecane from industrial and household cleaners and increasing application in the personal care industry will boost this product segment as 1-dodecane is used in the production of detergent alcohols. However, increasing consumption of bio-based detergent alcohols and alkyl aromatics is anticipated to replace 1-dodecane.

Application Insights

Polyethylene is the major application segment and accounted for around 57% of the market share, in terms of volume, in 2018. Construction is the leading application market for polyethylene compounds. Polyethylene is also used in the packaging sector and for prototype development on Computer Numerical Control (CNC) machines and 3D printers. High-density polyethylene offers easy processing at a lower cost, a good moisture barrier, and holds the ability to produce an opaque packaging product.

Low-density polyethylene is often preferred based on the field of application due to low production costs, heat seal-ability, high clarity and elongation, and softness. Demand forsynthetic lubricantsis expected to be driven by the implementation of stringent regulations regarding pollution control. Rising expenditure on R&D is also expected to play a major role in driving the demand for synthetic lubricants. Moreover, the wide scope of application of these lubricants is expected to further boost the market.

Regional Insights

The three largest producers of Linear Alpha Olefins (LAO) via ethylene oligomerization are Chevron Phillips, INEOS, and Shell. These companies have a significant presence in North America, Western Europe, and the Middle East. However, Western Europe is likely to experience a limited supply of ethylene and will continue to produce LAO through extractive distillation or full range process with minor capacity additions. Investments in the Middle East and North America are being focused on heavier LAOs. These regions are expected to target specialty grades of polyethylene, with a focus on the production of C6 and C8 LLDPE.

Rapid urbanization and industrialization in emerging economies of China and India are expected to drive product demand in polyethylene. Various government incentives and favorable regulatory scenario in China, India, Malaysia, and Indonesia have driven the growth of the manufacturing sector in the Asia Pacific. The product is widely utilized in polyethylene, detergent alcohols, synthetic lubricants, and plasticizers. Increasing the production of these products in the Asia Pacific is further expected to drive the regional market over the forecast period.

Alpha Olefin Market Share Insights

Industry participants are majorly focusing on new product development and long-term partnerships with raw material suppliers. Competitive factors that have had a deep impact on market growth include product portfolio, pricing, and manufacturing technology. Most manufacturers are multinational companies and therefore indulge in R&D activities for innovative and sustainable production methods.

These companies are setting up manufacturing units in developing countries to take advantage of future opportunities. Some of the key industry participants are Chevron Phillips Chemical Company LLC, Exxon Mobil Corporation, and Petrochemicals (Malaysia) Sdn. Bhd. Other manufacturers include INEOS Oligomers, Mitsubishi Chemical Corp., and Qatar Chemical Company Ltd (Q-chem).

ReportScope

Attribute |

Details |

The base year for estimation |

2018 |

Actual estimates/Historical data |

2014 - 2017 |

Forecast period |

2019 - 2025 |

Market representation |

Volume in Kilotons, Revenue in USD Million, and CAGR from 2019 to 2025 |

Regional scope |

北美, Europe, Asia Pacific, Central & South America, and Middle East & Africa |

Country scope |

U.S., Canada, Germany, U.K., France, Netherlands, China, India, Japan, South Korea, and Brazil |

Report coverage |

Volume & revenue forecast, company share, competitive landscape, growth factors and trends |

15% free customization scope (equivalent to 5 analyst working days) |

If you need specific information, which is not currently within the scope of the report, we will provide it to you as a part of customization |

赛格ments Covered in the Report

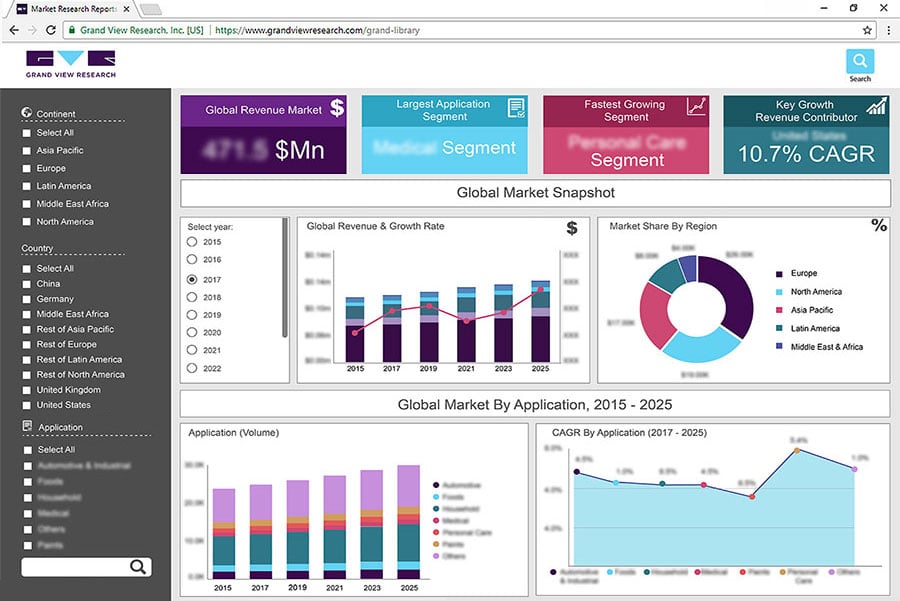

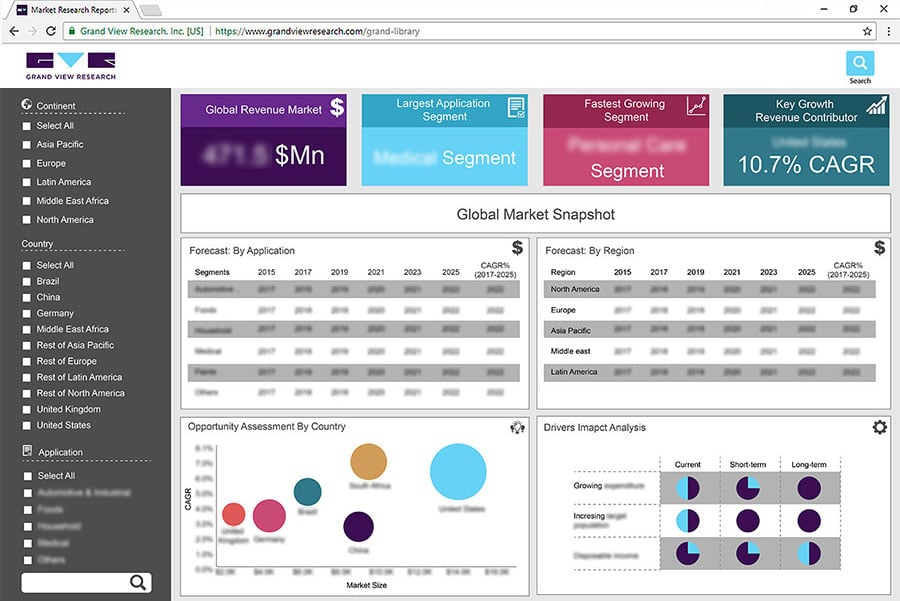

This report forecasts revenue and volume growth at global, regional, and country levels and provides an analysis of the latest industry trends in each of the sub-segments from 2014 to 2025. For this study, Grand View Research has segmented the global alpha olefin market report based on product, application, and region:

Product Outlook (Volume, Kilotons; Revenue, USD Million, 2014 - 2025)

1-Butene

1-Hexene

1-Octene

1-Decene

1-Dodecene

Others

Application Outlook (Volume, Kilotons; Revenue, USD Million, 2014 - 2025)

Polyethylene

Detergent Alcohol

Synthetic Lubricant

Others

Regional Outlook (Volume, Kilotons; Revenue, USD Million, 2014 - 2025)

北美

The U.S.

Canada

Europe

Germany

U.K.

France

Netherlands

Asia Pacific

China

India

Japan

South Korea

Central & South America

Brazil

Middle East & Africa