Polyolefin Market Size, Share & Trends Analysis Report By Product (PE, PP, EVA, TPO), By Application (Film & Sheet, Injection Molding, Blow Molding), By Region (North America, APAC), And Segment Forecasts, 2022 - 2030

- Report ID: GVR-2-68038-091-0

- Number of Pages: 131

- Format: Electronic (PDF)

- Historical Range: 2019 - 2020

- Industry:leyu888

Report Overview

The polyolefin market size was valued at USD 278.23 billion in 2021 and is anticipated to expand at a compound annual growth rate (CAGR) of 5.0% over the forecast period. The rapid development in emerging economies and increasing demand for beverages and lightweight fuel-efficient automobiles are expected to drive the market. The demand forplasticis rising due to its use in various industrial applications on account of its ability to form desired shapes and easy molding. Polyolefins are mainly manufactured from natural gas and oil through the polymerization of ethylene and propylene, respectively. It is made from monomers, hydrocarbons, and olefins and has a high level of processability, outstanding chemical stability, and prolonged durability. It is the most popular thermoplastic polymer, making it possible to employ it in a variety of applications like packaging, consumer goods, and fibers & textiles.

美国提供了一个为聚烯烃市场ccount of its highly developed industries, advanced processing & application technologies, skilled workforce, and growing R&D initiatives to encourage new product launches. The use of polyethylene, polypropylene, and ethylene-vinyl acetate in interior and exterior automotive components has fueled its demand in the automotive sector.

The U.S. is home to several major automotive manufacturers, such as General Motors, Ford, and Chrysler, who are also developing lightweight vehicles to comply with the Biden government’s carbon-neutral goal. With the abundant supply of polyethylene across the U.S. the market finds usage across several industries. On the contrary, the polypropylene market in the country is growing at a slower pace and is forecasted to not have any significant difference in terms of supply and demand. However, the overall market is likely to grow at a steady pace, owing to a wide array of application scope in industrial applications as well as in the automobile sector. The injection-molded grades are static load tested and high-grade ones are used majorly in films and sheets as well as in the packaging industry.

Product Insights

Ethylene-Vinyl Acetate (EVA) dominated the market with a revenue share of over 24.0% in 2021. Ethylene Vinyl Acetate increases transparency, flexibility, and toughness and is therefore used extensively in the processing and packaging industry primarily. They are also used vividly in footwear, automobile bumpers, athletic goods, and more. Moreover, rising demand for packaged food, bottles for fruit juices & milk, caps for food packaging, trays, drums, and other liquid food packaging owing to restrictions on the movement of people to reduce the spread of the COVID 19 is expected to drive the demand for polyethylene compounds. These factors have made EVA a popular material for multiple applications in developed economies and emerging economies alike.

聚乙烯在亚太市场largely dominated by China, India, and Japan on account of rapid industrialization. Developing construction & furniture sectors, along with the presence of major automotive industries and growing demand for sophisticated infrastructure are key factors driving the polyethylene industry in APAC. Government support to weatherize low-income households & meet transitioning standards for green buildings is anticipated to further drive the polyethylene demand in the region. Thermoplastic olefins have medium-high melt flow and have usage in diverse industries. Plastic thermoplastic olefins possess exceptional stiffness, high resistance, and dimensional stability. They are widely used in the automotive industry for external ornamentation along with many other sectors owing to non-degradation under UV exposure.

Application Insights

Film & sheet emerged as the dominant application segment in 2021 and accounted for the largest revenue share of more than 25.0% of the market where they are diversely applicable in food packaging, blown film bags, and more. Film and sheet plastic material are significantly used in industrial thermoforming and others. Polyolefins are durable and versatile plastics, which are widely used in the film and sheet industry. Plastics derived from polyolefins are often used in consumer goods as well as food packaging industries owing to their chemical-resistant, odorless, and nonporous nature. Shrink wraps and sheets are commonly used to wrap food articles, gift boxes, and several other such products. Injection Molding is another dominant application of polyolefins, which includes LDPE, LLDPE, EVA, HDPE, TPO, and PP.

The growing demand for PP injection molded parts for lighterElectric Vehicles(EVs) to manufacture the interior and exterior metal parts of cars are likely to benefit the global market. The reason for such vivid application scope owes to its lightweight characteristics along with high chemical resistance and excellent toughness at a lower temperature. APAC is a dominant market for polyolefins in electronics products like LEDs and assemblies,inkjet printers, electric tools housing, computer boards & housing, switches, and others. The growing trend of miniaturization of electronic gadgets is estimated to drive the blow-molded polyolefins market in the coming years.

Polypropylene is highly versatile when used as a fiber-forming material as compared to polyethylene. Olefin fibers are typically derived from olefins and are widely used in the textile industry globally. These are applicable in industries requiring high strength, low moisture absorption, and low static component polyolefins. The textile industry is the largest application market of polyolefin fibers, which are used in small volumes and for specific applications. China, Europe, and the U.S. are the largest consumers of these polyolefins. Under these polyolefins, polypropylene finds its major applications in home furnishing as well as industrial fabrics.

Regional Insights

亚太地区成为最主要的区域市场t and accounted for over 47.0% of the overall revenue in 2021. The region is expected to witness a steady growth rate from 2022 to 2030. The growth of the automotive sector along with increasing polymer consumption is anticipated to remain a key driving factor for the market growth in this region. APAC is also one of the largest consumers and producers of electrical and electronic products, such as equipment and wires among others, which further fuels the regional demand. The shift in the manufacturing landscape towards emerging economies, particularly China and India, is anticipated to positively influence market growth over the forecast period.

The region is home to several rapidly expanding industries as well, such as construction, automotive, and electronics, that present vast potential for polyolefin manufacturers. Most of the above countries are expected to witness high economic growth over the forecast period, despite slow growth in other developed regions, such as North America and Europe. Government support to support domestic manufacturing is likely to boost regional production levels and reduce the reliance on imports, which is expected to present lucrative opportunities for industrial manufacturers and even for polyolefin producers.

Europe is witnessing a significant growth in the film & sheet industry owing to the high demand for packaged food items across the region. Food-grade polyolefins have gained significant importance owing to the increasing consumption of packaged food in the region. Polypropylene is used in a significantly wide array of applications including packaging, plastic parts for the automotive industry, and more. Moreover, the polyolefin is widely used in Europe owing to the increasing number of automotive industries and consumer products in the region. Polypropylenes are also used in special devices, such as living hinges as well as in the textile industry.

These factors contribute to the increasing demand for polypropylene in Europe. Various infrastructural development and construction projects in the European region are anticipated to drive product demand as it has extremely beneficial characteristics that foster their application across a wide array of substrates. The recent announcement of the TEN-T Program to develop European transport infrastructure, includes the development of the Brussels railway, for upgrading the speed and connectivity of the North Sea-Mediterranean network. Germany is one of the major consumers of polyolefins owing to several upcoming industries, such as automotive, packaged food products, and more.

欧洲建筑业增长也是啊ne of the key consumers. The fastest-growing sectors in Europe are automotive and construction, which remains the major reason for increasing product demand. The revitalized automotive market, increasing consumer disposable income, and a rise in construction & infrastructural spending in these regions are likely to complement market growth. The rise in disposable income in Europe is forecasted to have a positive effect on the market in the near future. The recovery of the automotive industry in developing economies, such as the U.S. and Germany, is another key aspect.

Polyolefin consumption in the automotive industry is increasing owing to the strong demand for lightweight materials. North America and Europe are expected to exhibit a moderate growth rate from 2022 to 2030. Rapidly growing end-use industries, such as construction, packaging, and automotive, are anticipated to be the major driving force fostering industry growth. The presence of major petrochemical companies, such as BASF, Chevron, and CNPC, is expected to boost the regional market growth of China and other Asian countries including India, Thailand, and Vietnam.

Key Companies & Market Share乐鱼APP二维码

Companies are rapidly expanding their production capabilities to consolidate their market position. With governmental support in various countries focused on environmental concerns as well as an increase in construction activities, the market is expected to grow at a fast pace over the forecasted period. Several investments are observed in the market value chain to boost the green field plants. Several multinationals seek opportunities to invest in the European market to expand horizons.

For instance, in May 2022, BASF SE doubled its Irganox 1010 production capacity in Singapore by incorporating a second manufacturing line into the current production facilities. Irganox 1010 is a primary phenolic antioxidant that is sterically inhibited. It is mostly used in polyolefins and offers protection against thermo-oxidative degradation. These advancements enable the company to initiate the supply of circular plastics at the start of 2022. Some of the prominent players in the global polyolefin market include:

Sinopec Corp.

LyondellBasell Industries Holdings B.V.

PetroChina Company Ltd.

TotalEnergies

Chevron Corp.

Repsol

Dow

Exxon Mobil Corp.

Braskem

Borealis AG

Polyolefin Market ReportScope

Report Attribute |

Details |

Market size value in 2022 |

USD 294.59 billion |

2030年的收入预测 |

USD 436.76 billion |

Growth rate |

CAGR of 5.0% from 2022 to 2030 |

Base year for estimation |

2021 |

Historical data |

2019 - 2020 |

Forecast period |

2022 - 2030 |

Quantitative units |

Volume in million tons, revenue in USD billion, and CAGR from 2022 to 2030 |

Report coverage |

Volume forecast, revenue forecast, competitive landscape, growth factors, and trends |

Segments covered |

Product, application, region |

Regional scope |

North America; Europe; Asia Pacific; Central & South America; Middle East & Africa |

Country scope |

U.S.; Canada; Mexico; Germany; U.K.; France; Italy; China; India; Japan; Brazil; Saudi Arabia |

Key companies profiled |

Sinopec Corp.; LyondellBasell Industries Holdings B.V.; PetroChina Company Ltd.; TotalEnergies; Chevron Corp.; Repsol; Dow; Exxon Mobil Corp.; Braskem; Borealis AG |

Customization scope |

Free report customization (equivalent to up to 8 analysts' working days) with purchase. In addition or alteration to the country, regional & segment scope report, we will provide it to you as a part of the customization |

Pricing and purchase options |

Avail of customized purchase options to meet your exact research needs.Explore purchase options |

Global Polyolefin Market Segmentation

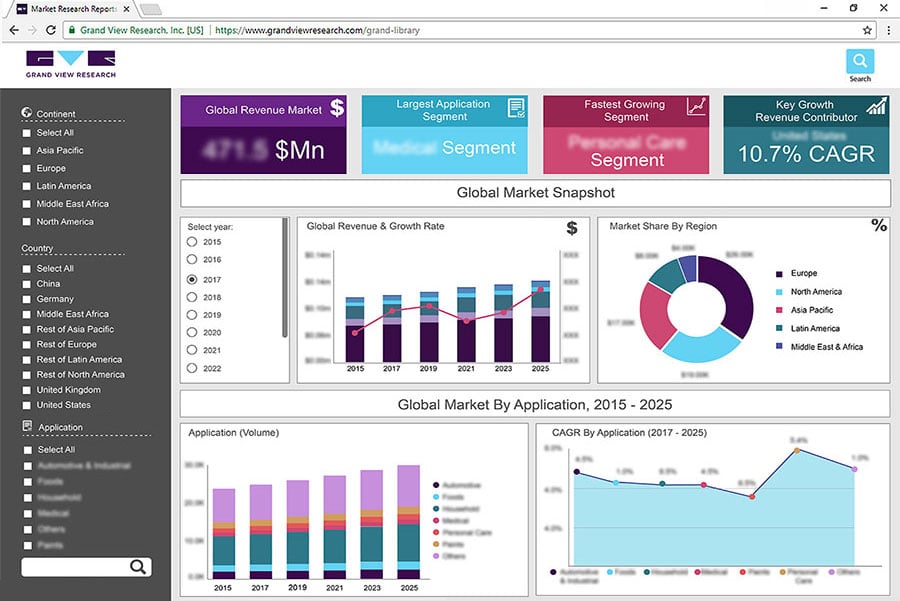

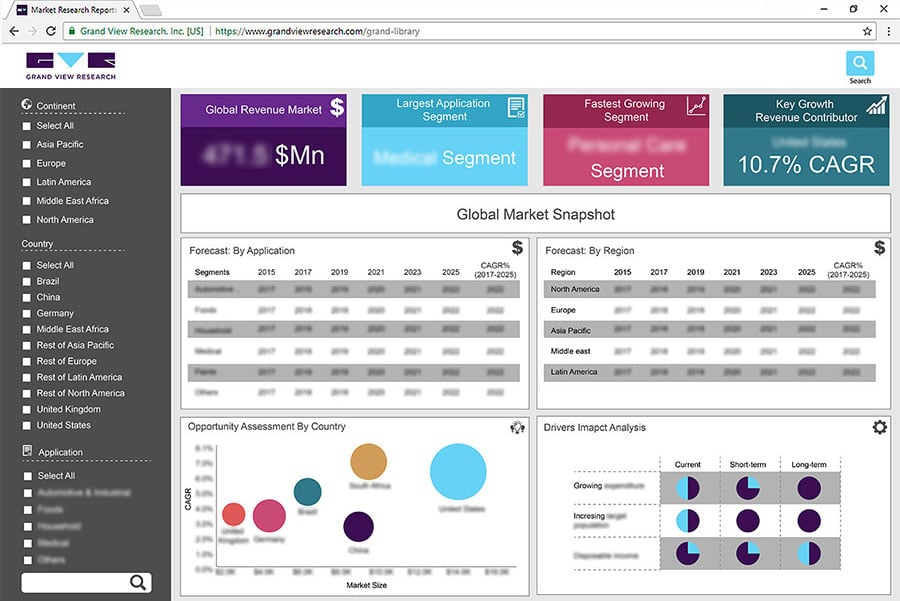

This report forecasts revenue growth at global, regional, and country levels and provides an analysis of the latest industry trends in each of the sub-segments from 2019 to 2030. For this study, Grand View Research has segmented the global polyolefin market report based on product, application, and region:

Product Outlook (Volume, Million Tons; Revenue, USD Billion,2019-2030)

PE

页

EVA

TPO

Others

Application Outlook (Volume, Million Tons; Revenue, USD Billion,2019-2030)

Film & Sheet

Injection Molding

Blow Molding

Profile Extrusion

Others

Regional Outlook (Volume, Million Tons; Revenue, USD Billion,2019-2030)

North America

U.S

Canada

Mexico

Europe

Germany

U.K.

France

Italy

Asia Pacific

China

India

Japan

Central and South America

Brazil

Middle East and Africa

Saudi Arabia

Frequently Asked Questions About This Report

b.The global polyolefin market size was estimated at USD 278.23 Billion in 2021 and is expected to reach USD 294.59 Billion in 2022.

b.The global polyolefin market is expected to grow at a compound annual growth rate of 5.0% from 2022 to 2030 to reach USD 436.76 Billion by 2030.

b.Film & sheet segment dominated the polyolefin market with a share of 25.32% in 2021. Polyolefin is diversely applied in food packaging, blown film bags, industrial thermoforming, and more.

b.Some key players operating in the polyolefin market include Sinopec Corporations, LyondellBasell Industries Holdings N.V., ExxonMobil Chemicals, and Petrochina Company Limited.

b.Key factors that are driving the polyolefin market growth include rising innovation in plastic technologies, the advent of cheap interior furnishings in automobiles, and strict industrial standards concerning carbon emissions.