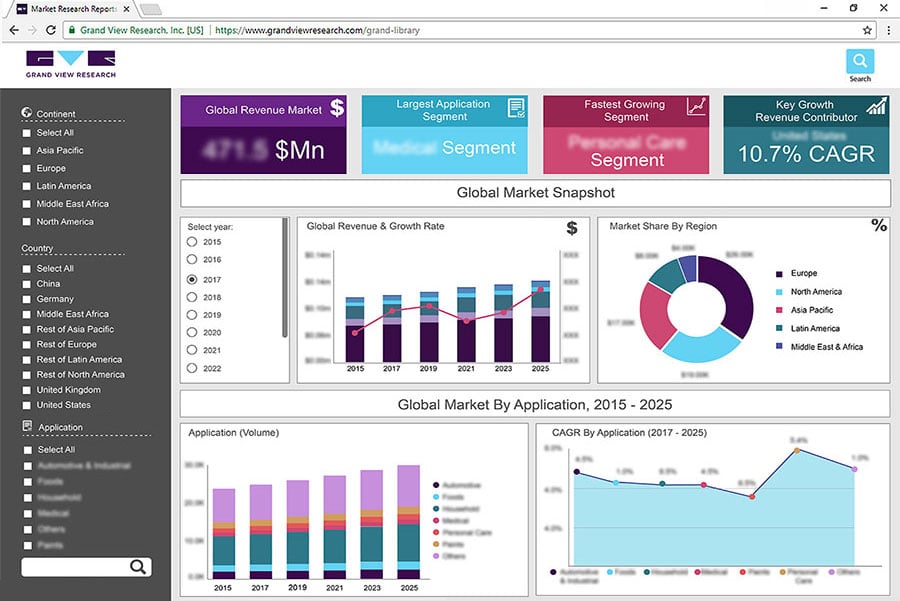

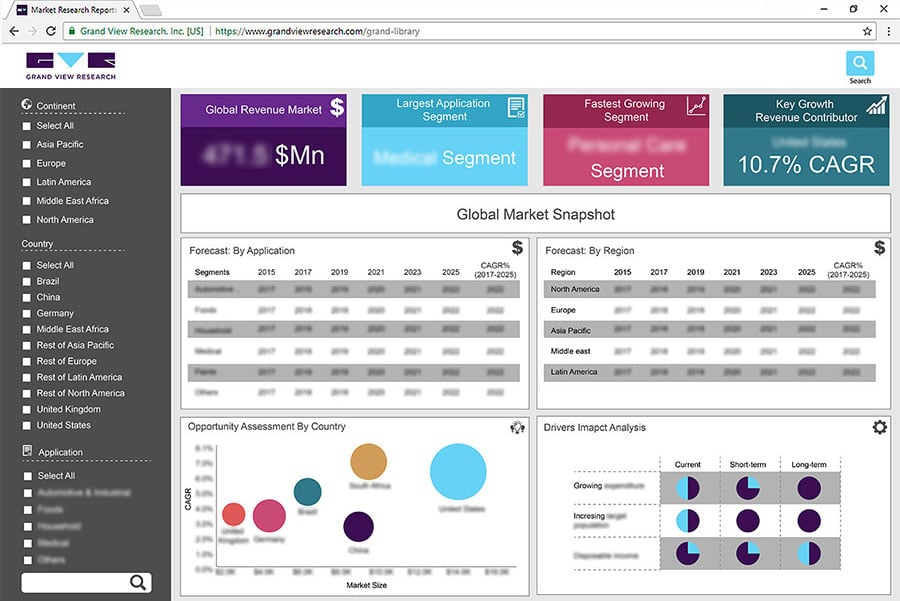

Catalyst Market Size, Share & Trends Analysis Report By Raw Material (Chemical Compounds, Zeolites, Metals), By Product (Heterogeneous, Homogeneous), By Application, By Region, And Segment Forecasts, 2020 - 2027

- Report ID: 978-1-68038-228-0

- Number of Pages: 115

- Format: Electronic (PDF)

- Historical Range: 2016 - 2018

- Industry:leyu888

Report Overview

The global catalyst market size was valued at USD 33.9 billion in 2019 and is expected to grow at a compound annual growth rate (CAGR) of 4.4% from 2020 to 2027. The escalating demand for catalysts from applications including chemical synthesis, petroleum refining, polymers and petrochemicals, and environmental is driving demand for process optimization, yield improvement, cost-saving, and energy-saving amongst the manufacturers globally. Additionally, environmental catalysts help manufacturers meet all the stringent mandates related to NOx, Sox, and carbon dioxide emissions. Shifting energy trends towards alternative fuels including biodiesel and shale gas fuel have propelled the demand for catalysts. Additionally, manufacturers seeking to add value to their feedstock or refining by producing value-added petrochemicals and chemicals such asmethanolandpolyolefins, have encouraged the demand for the product from petrochemicals and chemicals applications.

With the unprecedented outbreak of COVID-19, which has led to the closure of factories and manufacturing sites, there has been a significant decline in demand for oil, the first such instance in a decade. Additionally, the price war between Russia and KSA has led to a much decline in oil prices.

Global fuel demand is expected to drop by 15-10% in Q2, 2020 due to a halt in air travel and national lockdowns. A number of plants have been shut down and some are running but at reduced rates which may thus impact the market demand, especially in Iran, the U.S., China, India, France, Italy, and the U.K., which are some of the worst-hit economies.

Raw Material Insights

Chemical compounds emerged as the dominant raw material segment of the market representing a value share of 38.3% in 2019. Chemical compounds such assulfuric acid, hydrofluoric acid, andcalcium carbonateare used as catalyst raw materials for numerous applications in chemical,petrochemical, and polymer industries.

Metals used for dehydrogenation and hydrogenation are noble metals (platinum, palladium, ruthenium, rhodium, gold, and copper), non-noble metals (tungsten and molybdenum), and others such as nickel and cobalt are also used as key catalyst raw materials. These metals accelerate the process of breaking and re-arranging the aromatics and olefins to produce fractions such as alkanes and naphthenes.

Besides metals and chemical compounds, zeolites are another type of prominent raw material used in catalysts that are majorly used in catalyzing and adsorbent applications owing to their porosity and large surface area. Zeolites can accommodate a diversity of ions supported by their porous structure. These are obtained naturally and can also be manufactured commercially from crystallization reactions.

Product Insights

异构催化剂成为突出的product segment of the market with a value share of 72.1% in 2019. Homogeneous catalysts are converted into heterogeneous catalysts via solid supports to reduce their toxicity. Some common examples of heterogeneous catalysts include sulfated zirconia, sulfonated carbon materials, sulfonated silica materials, and sulfonated MOF materials.

The benefits of heterogeneous catalyst application include economical usage, simple separation of catalyst from products, and ease of application, which are likely to drive the segment. Further, gaining acceptance of heterogeneous catalysts over their homogenous counterparts for biodiesel production is likely to accelerate the growth of the catalyst market over the forecast period.

Homogeneous catalysts include products such as boric acid,phosphoric acid,hydrochloric acid, p-toluenesulfonic acid, and sulfuric acid. These catalysts are reported to show better performance in industrial and raw material reactions compared to their heterogeneous counterparts. However, these procedures create huge amounts of toxic waste, causing environmental hazards. This has prompted the need for environment-friendly catalysts, and the availability of biodegradable homogeneous catalysts such as methanesulfonic acid (MSA) has helped to meet such demands.

Application Insights

Chemical synthesis emerged as the prominent application segment of the market with a value share of 26.3% for heterogeneous catalysts in 2019. Chemical synthesis includes raw material and raw material chemistry wherein processes such as Contact, Haber, and converting ammonia tonitric acidinvolve the use of catalysts. Therefore, global chemical industry growth is expected to augment catalyst demand over the forecast period.

The application of catalysts in chemical synthesis is popular for their superior characteristics and properties such as the promotion of enantioselective processes, alkene, and alkyne activation & higher stability. Furthermore, they possess exceptional functional group tolerance, are cost-competitive, and do not require additional ligands. All the above-mentioned factors are responsible for increasing the use of catalysts in chemical synthesis and driving the segment growth.

Besides chemical synthesis, catalysts are primarily used in the cracking feedstock components in petroleum refining to increase the yield of high-quality products. The application of a catalyst promotes the optimization of hydrocracking reactions along with cost-saving and energy-saving benefits. This has favored the market growth in petroleum refining applications.

Regional Insights

Asia Pacific is likely to account for the largest value share corresponding to 33.7% in 2019, supported by the dominance of the automobile, petrochemicals, polymer, and chemical industries in China. China had a significant chunk of chemical and polymer production companies and thus, emerged as a manufacturing destination for chemical and petrochemical products owing to growing domestic demand and low manufacturing costs compared to the U.S. and the European Union countries. The market growth in the Asia Pacific is further augmented by the increasing FDI investments and lucrative growth opportunities projected by developing nations such as India and Vietnam.

North America is the second-largest market, owing to the evolving low sulfur and automotive mandates that necessitate the application of environmental catalysts in the region. The mounting consumption of gasoline in the U.S. is anticipated to escalate the demand for catalysts used for transforming heavy crude oil into light fractions such as kerosene, diesel, and gasoline. Further, the growth of the oil and gas and chemical sectors in Mexico is a key factor contributing to market growth in North America.

代表了3月的中东和非洲ket value share of 6.5% in 2019 are expected to project lucrative opportunities for petroleum refining catalysts on account of oil and gas industry dominance in Saudi Arabia, Oman, Kuwait, and Qatar, countries of the region. A surge in domestic demand in the automotive, construction, packaging, and pharmaceutical industries is expected to propel chemical manufacturers to boost their production output for polymers and petrochemicals in the Middle East.

Key Companies & Market Share Insights

Key manufacturers of the product including Albemarle Corporation and Johnson Matthey Plc hold significant market share in terms of segmental revenue. These players have global operations and diversified product portfolios. Prominent operational strategies of the market players include positioning in high-growth countries such as India and Vietnam, acquisitions, alliances, investments, and building and operating fully optimized supply chains. Key focus areas of product development among the manufacturers are in-house R&D, sustainable production, technology licensing, and customized product offerings. Production expansion in line with the evolving automotive mandates and maintaining long-term supply contracts with refineries and petrochemical plants along with business integration and technology licensing have helped the manufacturers remain competitive and maintain stable sales throughout. Some of the prominent players in the catalyst market include:

Albemarle Corporation

Haldor Topsoe A/S

BASF SE

Evonik Industries AG

LyondellBasell Industries Holdings B.V.

Catalyst Market Report Scope

Report Attribute |

Details |

Market size value in 2020 |

USD 35 billion |

Revenue forecast in 2027 |

USD 48 billion |

Growth Rate |

CAGR of 4.4% from 2020 to 2027 (Value) |

Base year for estimation |

2019 |

Historical data |

2016 - 2018 |

Forecast period |

2020 - 2027 |

Quantitative units |

Volume in kilotons, Revenue in USD million, and CAGR from 2020 to 2027 |

Report coverage |

Volume and revenue forecast, company ranking, competitive landscape, growth factors, and trends |

Segments covered |

Raw material, product by application, region |

Regional scope |

North America; Europe; Asia Pacific; Central & South America; Middle East & Africa |

Country scope |

U.S.; Canada; Mexico; U.K.; Germany; France; Italy; Spain; Russia; Netherlands; China; India; Japan; South Korea; Australia; Indonesia; Malaysia; Brazil; South Africa; Saudi Arabia |

Key companies profiled |

Albemarle Corporation; BASF SE; Evonik Industries AG; LyondellBasell Industries Holdings B.V.; Arkema; W. R. Grace & Co.-Conn.; W. R. Grace & Co.-Conn.; Johnson Matthey Plc; Axens SA; Clariant International Ltd.; ExxonMobil Corporation; Umicore |

Customization scope |

Free report customization (equivalent up to 8 analyst’s working days) with purchase. Addition or alteration to country, regional & segment scope. |

Pricing and purchase options |

Avail customized purchase options to meet your exact research needs.Explore purchase options |

Segments Covered in the Report

This report forecasts revenue growth at global, regional, and country levels and provides an analysis of the latest industry trends in each of the sub-segments from 2016 to 2027. For the purpose of this study, Grand View Research has segmented the global catalyst market report on the basis of raw material, product by application, and region:

Raw Material Outlook (Volume, Kilotons; Revenue, USD Million, 2016 - 2027)

Chemical compounds

Peroxides

Acids

Amines & others

Metals

Precious metals

Base metals

Zeolites

Others

Product By Application Outlook (Volume, Kilotons; Revenue, USD Million, 2016 - 2027)

Heterogeneous Catalyst

Chemical synthesis

Chemical catalysts

Adsorbents

Syngas production

Others

Petroleum refining

FCC

Alkylation

Hydrotreating

Catalytic Reforming

Purification

Bed grading

Others

Polymers and petrochemicals

Ziegler Natta

Reaction Initiator

Chromium

Urethane

Solid Phosphorous Acid catalyst

Others

Environmental

Light-duty vehicles

Motorcycles

Heavy-duty vehicles

Others

Homogeneous Catalyst

Chemical synthesis

Chemical catalysts

Adsorbents

Syngas production

Others

Petroleum refining

FCC

Alkylation

Hydrotreating

Catalytic Reforming

Bed grading

Purification

Others

Polymers and petrochemicals

Ziegler Natta

Reaction Initiator

Chromium

Urethane

Solid Phosphorous Acid catalyst

Others

Environmental

Light-duty vehicles

Motorcycles

Heavy-duty vehicles

Others

区域前景(体积,吨当量;Revenue, USD Million, 2016 - 2027)

North America

The U.S.

Canada

Mexico

Europe

Germany

The U.K.

France

Italy

Netherlands

Spain

Russia

Asia Pacific

China

India

Japan

South Korea

Australia

Indonesia

Malaysia

南美

Brazil

Middle East & Africa

South Africa

Saudi Arabia

Frequently Asked Questions About This Report

b.The global catalyst market size was estimated at USD 34.0 billion in 2019 and is expected to reach USD 35.1 billion in 2020.

b.The global catalyst market is expected to grow at a compound annual growth rate of 4.5% from 2020 to 2027 to reach USD 48.0 billion by 2027.

b.Heterogenous catalyst dominated the catalyst market with a share of 72.0% in 2019. This is attributable to their economical usage, simple separation of catalyst from products, and ease of application, which are likely to drive the segment growth.

b.Some key players operating in the catalyst market include BASF, W.R. Grace, Chevron Australia, Albemarle Corporation, Johnson Matthey, Beach Petroleum Ltd, Evonik Industries AG, DuPont, Carnarvon Petroleum Ltd, Apache Corporation, Cue Energy Resources Ltd, and ExxonMobil.

b.Key factors that are driving the market growth include the fact that catalysts help in reducing environmental emissions and manufacturing costs and favorable environmental regulations across industries and countries.