Powder Coatings Market Size, Share & Trends Analysis Report By Resin (Polyester, Epoxy-polyester), By Application (Consumer Goods, Automotive), By Region (APAC, Europe), And Segment Forecasts, 2021 - 2028

- Report ID: 978-1-68038-112-2

- Number of Pages: 203

- Format: Electronic (PDF)

- Historical Range: 2016 - 2019

- Industry:Bulk Chemicals

Report Overview

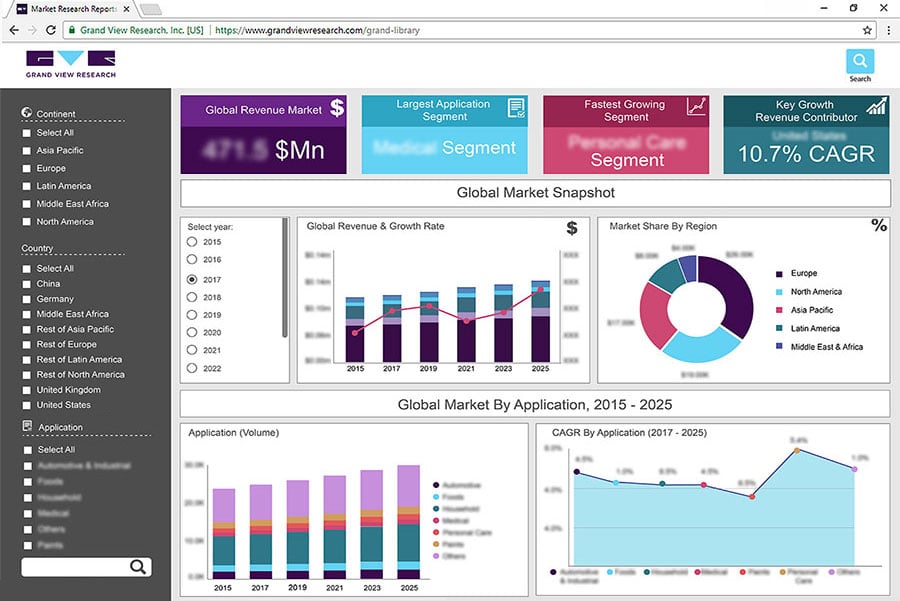

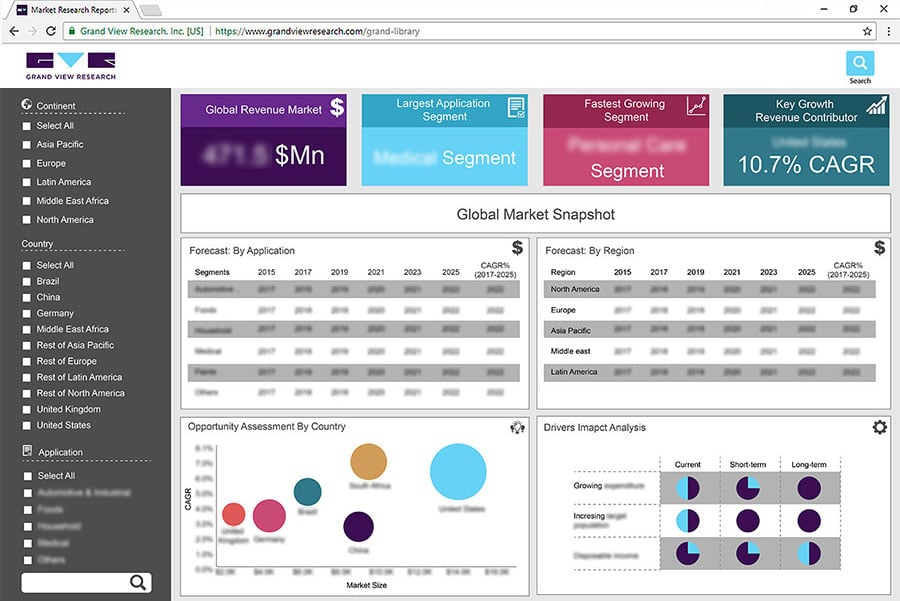

The global powder coatings market size was valued at USD 11.9 billion in 2020 and is expected to expand at a compound annual growth rate (CAGR) of 7.2%. The emerging economies of Asia Pacific and MEA regions have witnessed strong growth in non-residential sectors including consumer goods, IT, telecom, and retail resulting in growth in product demand. The growing number of consumer goods companies in India, China, and Singapore is expected to augment market development in the near future. Powder coatings have numerous advantages over other coatings, such as lower operating costs, immediate availability, negligible VOC emission, excellent appearance, and uniform thickness.

In addition, they are relatively easy to apply in thick layers of coating, which results in a smooth, uniform appearance.

A rise in the production of automobiles and the surge in demand for medical devices are expected to be major factors driving the market growth in developing nations including India, China, Brazil, and Mexico over the forecast period. Moreover, high product adoption in the furniture sector on account of its excellent performance, low operational costs, color availability, and custom properties, such as anti-corrosion and anti-bacterial functions, will stimulate market growth.

Powder coatings do not contain any solvents, which results in negligible emission of VOC in the atmosphere and reduced risk in combustion during application and storage. In addition, the powder can be easily washed off when it comes in contact with human skin, which reduces health hazards for operators.

Raw materials used in product manufacturing include thermoplastic and thermoset resins. Thermoplastic comprisesnylon, PVC,polyolefin, ABS, and polycarbonate coatings while thermoset comprises coatings made of epoxy, polyester,polyurethane, and acrylic coatings. Volatility in raw material prices affects the powder coating raw material pricing.

Powder Coatings Market Trends

Brazil, Russia, China, India and South Africa are the fastest growing economies of the world. Availability of cheap labor coupled with lower infrastructural costs has encouraged increasing number of manufacturers to expand their operations in this region. This has resulted in more employment opportunities, which in turn has boost the economy and impacted the income of people here.

消费者可支配收入增加耦合with the growing population has resulted in an increasing demand for automobiles, furniture, electronics, industrial and household appliances, agricultural equipment and other products. Powder is being used to coat various surfaces such as engine parts, pipes and fixtures, metal parts used in household appliances and other products. Thus, an increased demand of finished goods has led to a growing demand for powder coatings in these countries.

Conventionally, powder has been used to coat only certain parts of automotive such as chassis and engine parts. However, more and more automobile manufacturers are coating other parts such as radiators, bumpers, engine blocks, coil springs, shock absorbers, wheels, and mirror frames. Thus, demand for powder coating has been increasing in the automobile industry.

Increasing demand for automobiles such as cars and commercial vehicles in developing countries such as China, India and Brazil and replacement or spare parts in developed economies such as the UK and U.S. coupled with the increasing application of powder coatings on numerous parts of automobiles is expected to drive the powder coating market over the next few years.

Application of thin films around these areas may impair the leveling and film flow. Application of powder coatings inside corners may result in “Faraday’s cage effect” which results in low film thickness in these areas. The “Faraday’s cage effect” occurs as the electrically charged particles are attracted to the nearest point on the surface. Fewer lines of powder reach the deep ending of the surface, thus, resulting in formation of thinner layers in this area of the substrate. In cases, where powder coating cannot be used to cover edges, solvent coatings such as paints are used as substitutes to coat the substrates. This has resulted in limited growth of the powder coatings market affecting the market adversely.

Resin Insights

The polyester resin type segment accounted for 28.11% of the volume share in 2020 on account of beneficial properties of polyester, such as quick-drying, chemical resistance, temperature resistance, abrasion resistance, and surface protection. A surge in product demand in applications includingdoor handles, radiator grills, wheel rims, bumpers,bicycles, and metallic structural components will propel the segment growth over the forecast period.

Epoxy-Polyester (Hybrid) resin types are anticipated to witness the fastest CAGR over the forecast period on account of their properties, such as toughness, flexibility, weather ability, and low cost as compared to other coatings. These products are a mixture of both polyester andepoxy resinsand are mainly used for interior applications, such as furniture coatings.

Application Insights

消费品应用程序段主导the global market in 2020 accounting for 23.69% of the overall volume share. The segment is expected to witness significant growth over the forecast period. Growing purchasing power, high standards of living, and rapid urbanization are expected to drive the consumer goods sector, thereby boosting the product demand over the forecast period.

The use of powder coatings is predominant in consumer goods as these coatings do not containsolvents, exhibit higher flexibility than conventional liquid coatings, and comply with environmental regulations. Moreover, the rising demand for domestic appliances in India, China, Vietnam, the Philippines, and Thailand is expected to boost the product demand in the coming years.

The automotive application segment is expected to witness the fastest growth over the forecast period. Growing automobile production in the U.S., Mexico, Argentina, Brazil, South Africa, Indonesia, and China is expected to boost the product demand in automotive accessories. In addition, growth in demand for automobiles in emerging markets of China, India, Mexico, Brazil, South Africa, and Malaysia is expected to drive automotive sales in these countries.

Regional Insights

Asia Pacific dominated the powder coatings market and accounted for the largest revenue share of 39.58% in 2020. Infrastructure development in China and India is expected to boost the use of powder coating in architectural applications such as aluminum extrusions used in building facades, kitchen windows, doorframes, building facades, kitchen. However, key preference given to anodized aluminum extrusion is expected to restrict demand for powder coating in architectural applications in Asia Pacific over the forecast period.

Growth in automotive industry in the U.S. and rising concerns over VOC emissions from coating in automobile production is expected to boost the demand for powder coatings in the U.S. In addition, increasing automobile production in Mexico and shift of manufacturers from European Union is expected to increase the use of powder coating in the automobile industry of Mexico.

Increasing automotive production in Austria, Germany, Romania, Hungary, and Turkey are expected to boost demand for powder coating in the automobiles over the forecast period. In addition, REACH regulations for restricting VOC emission in the coating process have forced automotive manufacturers to utilize powder coatings in place of liquid coating. Reduction of VOC emission is expected to benefit automobile manufacturers in terms of receiving carbon credits. In addition, the increasing housing sector in Eastern Europe and Russia is expected to augment demand for MDF, which is expected to boost demand for powder coatings over the forecast period.

Key Companies & Market Share Insights

The global market is fragmented as the top industry players collectively accounted for 40% of the overall share. Manufacturers invest heavily in research & development activities and rely on technological developments to achieve competitive advantage through product differentiation and low cost. Moreover, manufacturers are focusing on integrating their operations through supply and distribution channels to expand their reach to individual consumers.

Fluctuating prices, as well as shortage, of raw materials are expected to be the major factors restraining market growth, as they result in higher production costs, thereby minimizing the profit. However, high demand for the product owing to its growing use in industries, such as automotive, construction, and furniture, is anticipated to drive market growth in the future. Some prominent players in the global powder coatings market include:

Akzo Nobel N.V

The Sherwin-Williams Company

PPG Industries, Inc.

BASF SE

DSM

Valspar

Arkema S.A.

Bayer AG

Powder Coatings Market ReportScope

Report Attribute |

Details |

Market size value in 2021 |

USD 12.8 billion |

Revenue forecast in 2028 |

USD 20.8 billion |

Growth rate |

CAGR of 7.2% from 2021 to 2028 |

Base year for estimation |

2020 |

Historical data |

2016 - 2019 |

Forecast period |

2021 - 2028 |

Quantitative units |

Volume in kilo tons, revenue in USD million/billion, and CAGR from 2021 to 2028 |

Report coverage |

Volume forecast, revenue forecast, company ranking, competitive landscape, growth factors, and trends |

Segments covered |

Resin, application, region |

Regional scope |

North America; Europe; Asia Pacific; Central & South America; Middle East & Africa |

Country scope |

美国;加拿大;墨西哥;德国;英国;法国;意大利; Russia & CIS Countries; Benelux; Turkey; Spain; Switzerland; Sweden; Poland; Austria; Norway; Denmark; Finland; Portugal; Czech Republic (CZ); Slovenia; China; India; Japan; Thailand; Brazil; Argentina; Saudi Arabia; South Africa |

Key companies profiled |

Akzo Nobel N.V; The Sherwin-Williams Company; PPG Industries, Inc.; BASF SE; DSM; Valspar; Arkema S.A.; Bayer AG |

Customization scope |

Free report customization (equivalent up to 8 analyst’s working days) with purchase. Addition or alteration to country, regional & segment scope |

价格和购买该俱乐部ns |

Avail customized purchase options to meet your exact research needs.Explore purchase options |

Segments Covered in the Report

This report forecasts volume and revenue growth at a global, regional, and country levels and provides an analysis of the latest industry trends in each of the sub-segments from 2016 to 2028. For the purpose of this study, Grand View Research has segmented the global powder coatings market report on the basis of resin, application, and region:

Resin Outlook (Volume, Kilo Tons; Revenue, USD Million, 2016 - 2028)

Epoxy

Polyester

Epoxy-polyester (Hybrid)

Acrylic

Polyurethane

Others

Application Outlook (Volume, Kilo Tons; Revenue, USD Million, 2016 - 2028)

Consumer Goods

Architectural

Automotive

General Industries

Furniture

Others

区域前景(卷ume, Kilo Tons; Revenue, USD Million, 2016 - 2028)

North America

U.S

Canada

Mexico

Europe

Germany

U.K.

France

意大利

Russia & CIS countries

Benelux

Turkey

Spain

Switzerland

Sweden

Poland

Austria

Norway

Denmark

Finland

Portugal

Czech Republic (CZ)

Slovenia

Asia Pacific

China

India

Japan

Thailand

Central and South America

Brazil

Argentina

Middle East and Africa

Saudi Arabia

South Africa

Frequently Asked Questions About This Report

b.The global powder coatings market size was estimated at USD 11.9 billion in 2020 and is expected to reach USD 12.8 billion in 2021.

b.The global powder coatings market is expected to grow at a compound annual growth rate of 7.2% from 2021 to 2028 to reach USD 20.8 billion by 2028.

b.消费品应用程序段主导the powder coatings market with a share of 23.69% in 2020. This is attributed to the rising product demand from various applications such as air conditioner cabinets, refrigerators, vacuum cleaners, microwave oven cavities, and others.

b.Some key players operating in the powder coatings market include Akzo Nobel N.V., PPG Industries, Inc., The Sherwin-Williams Company, Axalta Coating Systems, Kansai Paint Co., Ltd., Nippon Paint Holdings Co., Ltd., Koninklijke DSM N.V., Bayer AG, and Eisenmann.

b.Key factors that are driving the powder coatings market growth include supportive environmental regulatory, and rising product applications in automotive, consumer goods, and general industrial sectors.

b.The polyester resin type segment accounted for 28.11% of the volume share in the powder coatings market in 2020 on account of beneficial properties of polyester, such as quick-drying, chemical resistance, temperature resistance, abrasion resistance, and surface protection.

b.The Asia Pacific region was the largest powder coatings market in 2020 and accounted for a revenue share of 39.31%.